Sensor Based Maintenance at PFW

26 July 2023

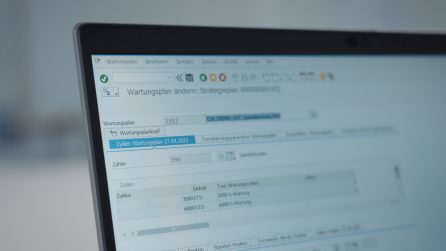

Evora customer PFW raised the following question: Do we perform our maintenance operations at the frequency needed? The answer was found in implementing a sensor based maintenance solution using SAP Intelligent Asset Management products: SAP IoT, SAP Asset Central and SAP Predictive Asset Insights.

Read more about how Evora helped to develop a system that closed the gap between PFW’s machinery and the ERP system. With the use of sensor data, runtime-based maintenance was to be made possible in the first step since this allowed for the greatest economic benefit. At the same time, PFW is able to build more complex use cases like predictive maintenance within the same system in following phases.

Download

Learn more

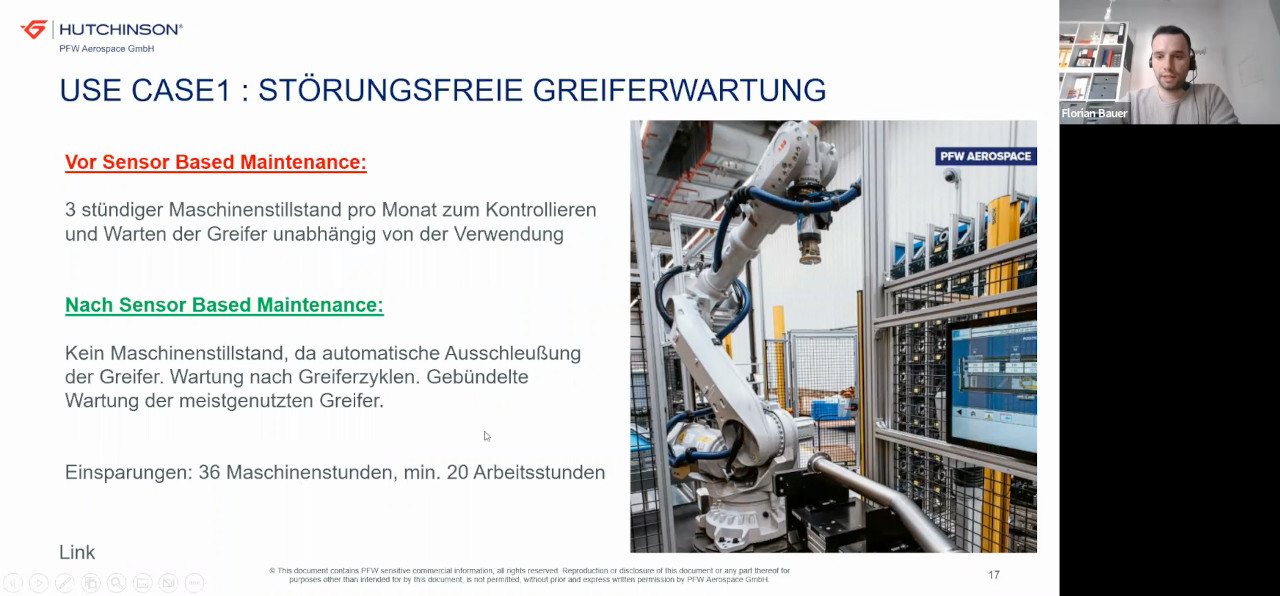

Watch full webinar recording (in German)How to turn IoT data into competitive advantage was the topic of the virtual SAP Innovation Roundtable with PFW’s project lead. Watch the recording to learn about the vision on how sensor-based planning in maintenance helped to save costs, time and energy for PFW. Please note: the recording is in German, and registration is required to access. Feel free to reach out to our team to discuss your needs.

Webinar Recording